- Home

- Spotlight on a collaboration between UNIGE and GF AgieCharmilles

Spotlight on a collaboration between UNIGE and GF AgieCharmilles

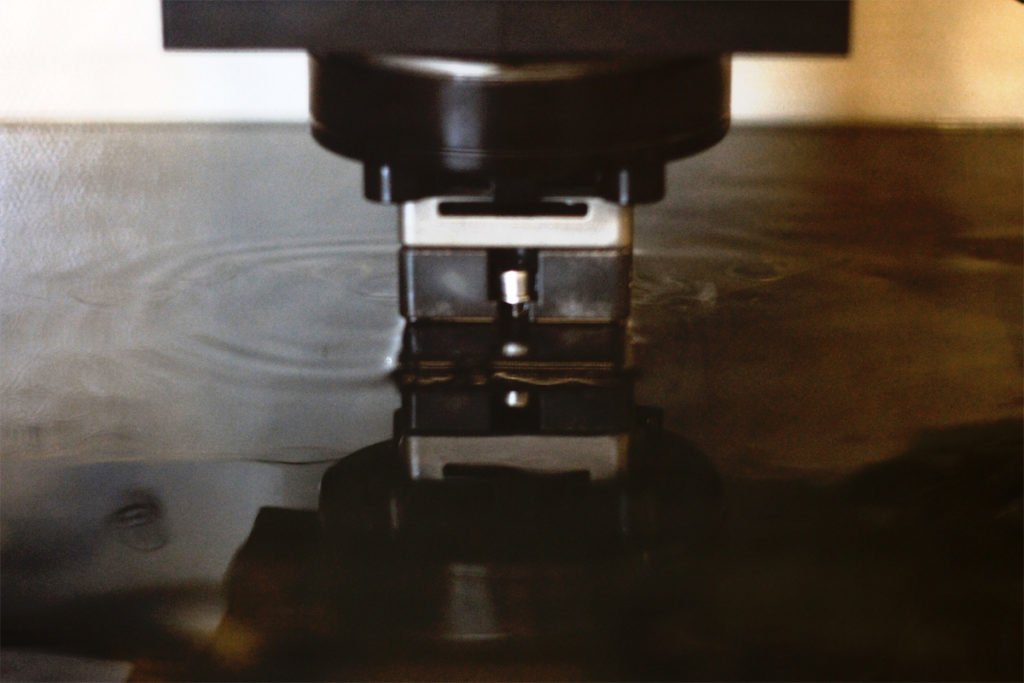

The project between the University of Geneva and GF Agie Charmilles is a great example of collaboration between industry and MaNEP’s researchers. It targets new surface treatments for injection moulds manufactured by electro-erosion.

Interview with Roberto Perez

Head of Applied Research Innovation

GF AgieCharmilles

R&D and innovation can be critical for the export industry in Switzerland.

In this respect, what are the main challenges GF AgieCharmilles is facing today ?

R.P: Our main challenges are related to our costs in relation to competition elsewhere. The Swiss franc remains too high with respect to other currencies. In order to develop our markets, we definitively need to be innovative and offer the added value of quality and precision that our customers expect from a Swiss brand. From the geographic perspective, as the market has shifted to Asia, we must manage the distance barrier by developing our local marketing forces and improve our communication worldwide. Finally, we must focus on segments that can sustain our growth.

During the last years, you have been actively involved in cooperative work with the NCCR MaNEP – team of Dr. Jorge Cors, University of Geneva. Could you please explain the dynamics of that work and the main contributions for your company ?

R.P: The work with MaNEP is an excellent example of a successful collaboration in a fast changing environment. Besides bringing excellence and expertise in research, the partnership with MaNEP has the advantage of proximity, access to leading-edge resources, and flexibility to cooperate with our R&D teams in the best way, in order to respond to sophisticated requests from our customers and to pressure from competition. For instance, our common project “Edelweiss” focuses successfully on delivering new textures and surface properties for the ICT mould market. These developments are at the heart of current market needs, but need integration of expertise in material science which are not part of our capabilities, and this within a short-term scope.

Could you please explain some concrete applications or breakthroughs of the developed technologies ?

R.P: As an interesting exploitation of a collaboration project with MaNEP, we are currently making application tests with key customers of the technologies developed for strengthening the machined parts with refractory alloys and ceramics at the surface. Many customers are very interested in these technologies, as they could apply to surfaces subject to high wear and abrasion, which render standard coating methods impractical. If successful, these new technologies could decrease greatly the operational costs.

Have you identified the main particular features driving the success of the projects ? Creativity ? Discipline ? Proximity ?

R.P: All such factors are important and are part of the advantages of our collaboration. It is known that creativity results very often from bringing various expertises together, but this is surely enhanced and best exploited by a disciplined team-work. If we add flexibility, we have all the ingredients to be successful in the middle of the current turmoil.

To what extent is this kind of applicative research important for the future of your company ?

R.P: Our technology has reached maturity and it becomes more difficult to differentiate from competitors. These joint research projects focused on high-business potential applications help us to provide new strategic directions for sustaining our organisation growth, but also contribute to our bottom line while tackling short term market demands with the appropriate means.

What other benefits (i.e. not scientific nor technical) have been obtained from the partnership ?

R.P: From the strategic point of view, it is key for our organisation to be part of a network which provides different types of opportunities besides those related to science and technology; for instance, new business perspectives, branding, support from the government and last but not least, the development of engineers and researchers of both sides and the potential job opportunities for young researchers and engineers from the academy.

The CTI has fully supported these activities, as well as the SNF. Some comments about their support ?

R.P: This support has become a key resource for our innovation teams, in constant need of new ideas and means for taking the risks associated with their implementation. We are very grateful to the CTI and SNF, especially for the outstanding support they have provided to us during difficult times for our industry.

Is there any suggestion or recommendation you would like to make in order to perform even better in the future ?

R.P: It would be interesting to exchange about our experience with representatives of these organisations and with other participants in CTI and SNF programs, on topics which are of course in the public domain.

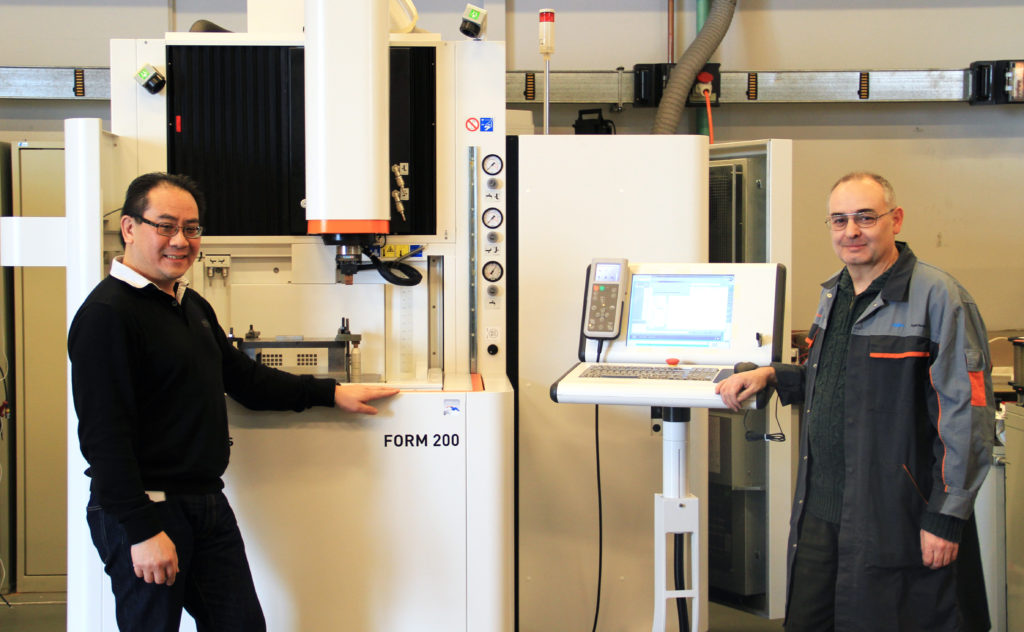

GF AgieCharmilles is one of the world leader in the machine tool industry, facing fierce competition from other manufacturers. In response to this competition, it had to enter the growing market of coated metal parts to maintain its leading position.Combining surface science tools, metallurgy and X-ray fluorescence analysis, a MaNEP project led by Dr Jorge Cors has met the challenge to provide GF AgieCharmilles with the technology it needed to manufacture substantially better tools. This developments succeeded within only two years, and has supported GF AgieCharmilles to secure this strategic market with key customers.

www.gfac.com